|

|

| ducatimeccanica.com - home |

|

3.2 Fuel system First of all, ensure that, with the engine running, fuel flows continuously from the tank to the Carburetor as vibrations from the engine or from the road surface could reduce fuel flow.

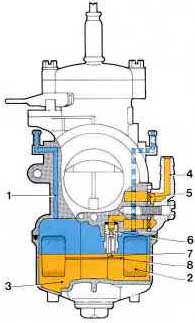

fig.9 It is therefore advisable to use fuel taps and pipes of adequately large size. 3.2.1 Selection of the needle valve size For a motorcycle with gravity feed from a fuel tank, the fuel inlet valve size, stamped on the seat of the needle-valve itself, should always be 30 % greater than the main jet size. In case of malfunctioning, you may find that the needle valve size is too small when running the engine at full throttle for a long stretch and that the engine rpm falls, due to the progressive weakening of the carburation. Conversely, you may get repeated flooding in use where the needle valve seat size is too large.

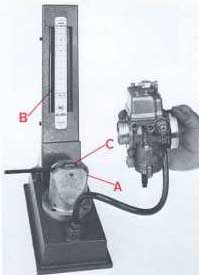

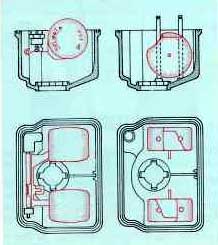

fig.10 On a motorcycle where fuel is supplied to the Carburetor via a fuel pump, a needle valve of smaller size than the main jet is required because the boost pressure is much greater than the pressure head obtainable with the gravity tank. After having primed the air pump of the vacuum gauge by means of the cam C, you will see the mercury in the column rising due to the action of air compressed by the pump; if the mercury column tends to go down, check the complete fuel circuit for leakage; if the fuel circuit is in good working order, the pressure leakage is due to the needle-valve and therefore check it for wear or obstruction and, if necessary, replace it with a complete new assembly of the appropriate size and type. 3.2.2 Selection of the float The floats currently used are: dual floats connected together (fig 11) and floats with separate parts (fig 12) In the first type, the floats operate together, while in the second type they can move independently along two guides in the float chamber.

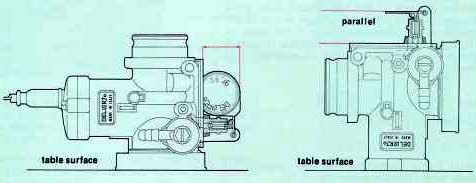

fig. 11 (left) fig. 12 (right) This latter type is particularly suitable for Carburetor s on racing motorcycles because it maintains a constant level even in the most arduous conditions of use. Check the correct float level position as follows: for connected floats, hold the Carburetor body in the position shown in fig. 13 and check that the float is at the correct distance from the Carburetor body face as specified in the table. for the floats with independent parts, hold the Carburetor upside down (fig. 14) and check that the float arm is parallel to the Carburetor face. Whenever the float or float-arm position does not correspond to the proper specified level setting or is not parallel to the float chamber face, bend the float arms carefully to set the correct position.

fig. 13 |

||||||||||||||||

| B A C K |

|

N E X T | ||||||||||||||