|

|

| ducatimeccanica.com - home |

|

3.3 Starting from cold

Although there are normally no difficulties starting the engine when it is hot, it is necessary to alter the carburation somewhat when the engine is cold. When starting from cold, the Carburetor has to deliver a fuel mixture rich enough to produce in the cylinders a mixture ratio very close to the stoichiometric ratio; due to the low engine temperature, a large part of the fuel does not atomise completely or condenses on the cold portions of the in let tracts and the cylinders themselves. It should therefore be clear that, at the moment of ignition, it is the actual fuel-air ratio which reaches the cylinder that is important and not the amount of fuel, atomised or not, delivered by the Carburetor . 3.3.1. Independent starting circuit.

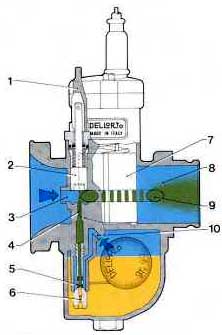

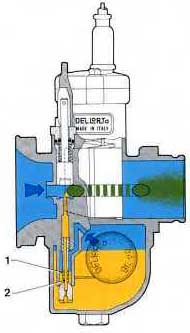

It is called independent because the starting device operates with its own circuit including a starter jet, emulsion tube and a starter valve (fig. 15) fig. 15 3.3.2. Selection of emulsion tube and starter jet

fig.16

The operation of the independent circuit starting device can be divided into two parts: The channel size (4) is such that it creates an optimum vacuum in the starter valve chamber, at the emulsion tube outlet both for starting up and for the mixture required by the engine for its running and warming up. Therefore, varying the position or the size of the starter emulsion tube holes will change the amount of fuel delivered; the mixture ratio is controlled by the starter jet size and therefore a larger jet causes enrichment and vice-versa. Difficulties in starting the engine can occur when this mixture is too rich or too lean and you can see this from the spark plugs. After some starting attempts, remove the spark plugs and, if these are wet, the mixture is too rich and you will therefore need an emulsion tube with holes higher up. Conversely, if the spark plugs are found to be dry, the mixture is too lean and an emulsion tube with holes lower down is therefore needed. If the engine stalls when the engine is first started from cold before it has been running for at least a minute with the starting device on, you will need to reduce the starter jet size because of an over-rich mixture or increase it if the engine stalls because of a lean mixture. Check that the starter valve closes completely afterwards to avoid any mixture blow-by which may later disturb the carburation. Therefore check that with the starting device off, the control lever is free to move a little on its pivot pin or that, where a remote cable control is fitted, the cable has at least 1-2 mm of free play. 3.3.3 - The flooding-plunger cold starting device

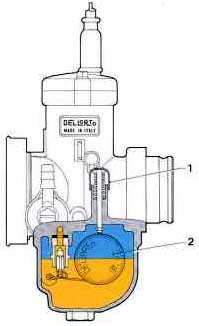

The starting device with a flooding plunger, or tickler, is shown in figure 17 and uses the normal main and idle circuits. fig. 17 |

||

| B A C K |

|

N E X T |